After three decades working with building electrical systems, you’d think I’d breeze through 12V van wiring. Wrong. Vehicle electrical systems have their own peculiarities, and I’ve learned them all the expensive and occasionally dangerous way.

Welcome to the Split Charging And Alternator Wiring Guide. This guide is everything I wish someone had told me before I connected my first leisure battery to my alternator.

This guide is everything I wish someone had told me before I connected my first leisure battery to my alternator. Not the sanitized version. Not the perfect installations. The actual reality of split charging, what genuinely works, what’s dangerous rubbish, and how to avoid setting fire to your van.

Why Split Charging Actually Matters

Your van has two electrical systems that need to stay separate but also work together:

Starter battery system:

- Powers starter motor (200-400A draw)

- Powers vehicle electronics (lights, ECU, dashboard)

- Must always have enough charge to start engine

- Typically 60-100Ah capacity

- If this dies, you’re stranded

Leisure battery system:

- Powers your conversion (lights, fridge, pump, heater)

- Can be discharged heavily without issues

- Typically 100-200Ah capacity

- If this dies, you’re uncomfortable but not stranded

The problem: Both batteries need charging from the alternator, but:

- Leisure battery shouldn’t drain starter battery

- Starter battery shouldn’t drain leisure battery

- Both need charging when engine runs

- Neither should interfere with vehicle electronics

- System must be safe and legal

Get this wrong and you’re either stranded with a flat starter battery or melting cables or damaging your alternator (happened once, £280 to replace).

Understanding Your Alternator (Critical Background)

Before you wire anything, understand what you’re working with.

What Your Alternator Actually Does

Your alternator converts mechanical energy (from the engine) into electrical energy to:

- Charge the starter battery

- Power vehicle electrical systems

- (Potentially) charge your leisure battery

Typical van alternator specs:

- VW Transporter T5/T6: 140-180A

- Ford Transit Custom: 150-180A

- Mercedes Sprinter: 180-220A

- Older vans (pre-2010): 90-120A

But: That’s maximum output. Typical driving output: 60-80A total.

That’s split between:

- Vehicle systems: 15-30A (lights, ECU, dashboard, fans, etc.)

- Starter battery maintenance: 5-15A (once started, just maintaining)

- Available for leisure: 30-60A

Important: Modern vans with lots of electronics (heated seats, parking sensors, cameras, climate control) use more power. Less available for leisure charging.

Alternator Output Voltage

This is critical and often misunderstood.

Typical alternator output: 13.8-14.4V (varies with RPM, temperature, load)

What batteries actually need:

AGM batteries:

- Bulk charge: 14.4-14.7V

- Absorption: 14.4V

- Float: 13.8V

Lithium batteries:

- Bulk charge: 14.4-14.6V

- Absorption: 14.6V

- No float needed

The problem: Many alternators regulate to 14.2V maximum. This is fine for starter batteries but inadequate for proper AGM charging and borderline for lithium.

My Transit Custom alternator: 14.3V at idle, 14.2V at cruise. Just barely adequate.

Solution: DC-DC charger boosts voltage to correct level regardless of alternator output.

Can Your Alternator Handle Leisure Charging?

Rule of thumb: If your alternator is 120A or more, you can safely draw 30A for leisure charging.

Check your alternator rating:

- Look on the alternator body (stamped rating)

- Check vehicle manual

- Google “your van model + alternator amperage”

My vans:

- 2008 T5: 140A alternator (fine for 30A leisure)

- 2015 Transit Custom: 150A alternator (fine for 30A leisure)

- 2017 Transit Custom: 150A alternator (fine for 30A leisure)

Warning signs your alternator is struggling:

- Dimming lights when leisure battery charging starts

- Battery warning light flickers

- Alternator getting very hot (can smell it)

- Alternator making noise (whining or grinding)

- Vehicle electronics glitching

I killed an alternator in van #2: Used a 30A DC-DC charger on a van with a weak 90A alternator (2006 Vivaro). Alternator lasted 8 months then failed. Cost: £280 replacement.

Lesson: Check alternator capacity before sizing your charging system.

Smart Alternators (2015+ Vans)

Modern vans (2015 onwards typically) have “smart alternators” designed for fuel efficiency.

How they work:

- Only charge battery when needed (not constantly)

- Reduce output when cruising (better MPG)

- Increase output when braking (regenerative)

- Regulate voltage based on battery condition

The problem for split charging:

- Output voltage varies (13.5-14.8V)

- May not charge leisure battery consistently

- Simple split charge relays don’t work well

- Can confuse basic DC-DC chargers

My experience: 2017 Transit Custom has smart alternator. Basic split charge relay was useless (only activated occasionally). Upgraded to DC-DC charger with smart alternator detection (Victron Orion) – works perfectly.

Solution: Use a DC-DC charger with smart alternator compatibility (most modern DC-DC chargers handle this).

Split Charging Methods: The Honest Comparison

I’ve used three main methods across four vans. Here’s what actually happens.

Method 1: Split Charge Relay (Voltage Sensing)

What it is: An automatic relay that connects batteries when it detects alternator voltage (13.5V+) and disconnects when voltage drops (engine off).

Cost: £25-£60

How it works:

- Engine starts → voltage rises to 13.8V+

- Relay detects voltage, closes contacts

- Starter and leisure batteries connected

- Both charge from alternator

- Engine stops → voltage drops to 12.5V

- Relay opens, batteries isolated

Suitable for:

- Older vans (pre-2015, non-smart alternators)

- AGM batteries only (not lithium)

- Budget builds (£500-£1000 total electrical)

- Light usage (30-50 nights/year)

Popular models:

- Ring RSCDC30 (30A, £28)

- Durite 0-727-33 (140A, £35)

- Voltage Sensitive Relay (VSR) generic (£25-£40)

Pros:

- Cheap (£25-60)

- Simple to install

- No programming needed

- Works with any battery type (if voltage is correct)

- Reliable (no electronics to fail)

Cons:

- No control over charging voltage (uses whatever alternator provides)

- Can overcharge or undercharge depending on alternator

- Doesn’t work well with smart alternators

- Both batteries connected = both can drain if relay fails

- Slow charging (limited by alternator voltage)

- Can’t charge lithium properly (wrong voltage profile)

Cable sizing for split charge relay:

For 30A relay with 3m cable run:

- Minimum: 6mm²

- Recommended: 10mm²

- Safe: 16mm²

Installation complexity: Simple. Four connections:

- Positive from starter battery to relay

- Positive from relay to leisure battery

- Negative to chassis (earth)

- Sense wire to ignition (optional on some models)

Verdict: Adequate for budget builds with AGM batteries and older vans. Not suitable for modern vans or lithium batteries. I wouldn’t use one again now DC-DC chargers are affordable.

Method 2: Battery Isolator (Diode-Based)

What it is: Uses diodes to allow current flow in one direction (alternator to batteries) but prevent reverse flow (batteries draining each other).

Cost: £45-£95

How it works:

- Diodes allow charging current from alternator to both batteries

- Prevent batteries from discharging into each other

- No relay, no voltage sensing, always connected

Pros:

- Simple (no moving parts)

- Automatic (no sensing required)

- Cheap-ish (£45-95)

Cons:

- Voltage drop across diodes (0.6-0.8V lost)

- Both batteries charge at same voltage (not ideal if different types)

- Gets hot under load (needs cooling)

- Inefficient (wastes power as heat)

- Outdated technology

My experience: Never used one. Tested a mate’s setup (Sterling Battery-to-Battery isolator, £75).

What I observed:

- Warm to touch when charging

- Voltage at leisure battery: 13.6V (alternator was 14.3V – 0.7V drop)

- This is inadequate for AGM (needs 14.4V minimum)

- Basically useless for proper charging

Verdict: Don’t buy these. Worse than split charge relays in every way. Outdated technology that wastes voltage.

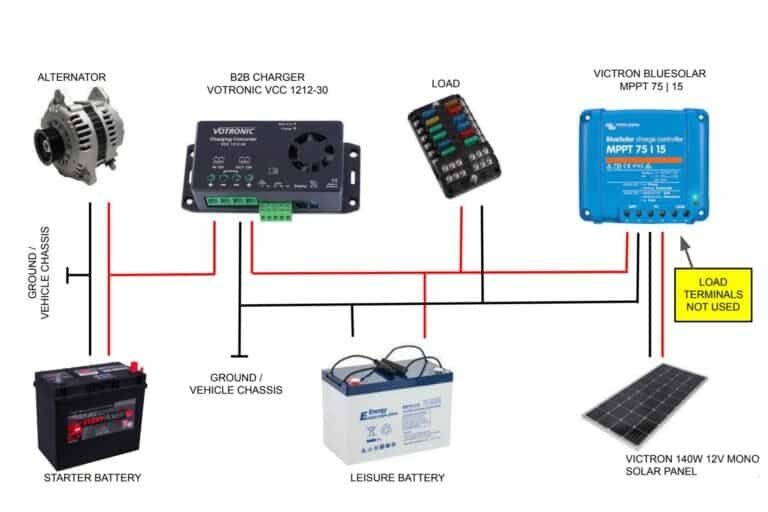

Method 3: DC-DC Battery Charger (The Right Way)

What it is: Intelligent power supply that takes alternator voltage (12-14.4V) and converts it to optimal charging voltage (14.2-14.6V) for your specific battery type.

Cost: £100-£220

How it works:

- Monitors both starter and leisure batteries

- Only activates when starter battery is charged (13.5V+)

- Draws power from alternator

- Converts (boosts/bucks) to correct voltage for leisure battery

- Charges in proper 3-stage profile:

- Bulk: Maximum current until 80% full

- Absorption: Reduced current, maintains voltage

- Float: Maintains full charge (AGM only, not lithium)

- Protects both batteries from damage

Suitable for:

- Modern vans (2010+, especially 2015+ with smart alternators)

- Any battery type (selectable profiles: AGM, Gel, Lithium)

- Regular use (50+ nights/year)

- Proper battery charging

- Anyone who wants reliability

Popular models:

Budget (£100-£140):

- Renogy 20A DC-DC (£105)

- CTEK D250SE (£125)

- Sterling BB1230 (£135)

Mid-range (£150-£180):

- Victron Orion 12/12-18 (£157) – what I use

- Renogy 40A DC-DC (£165)

- CTEK D250SA + Smartpass (£180)

Premium (£190-£220):

- Victron Orion 12/12-30 (£210)

- Sterling BB1260 (£215)

Amperage guide:

- 18A charger: Fine for 100-150Ah batteries

- 30A charger: Better for 150-200Ah batteries

- 40A charger: Overkill unless you have 200Ah+ and short driving times

Pros:

- Proper charging voltage (extends battery life)

- Works with smart alternators

- Selectable battery profiles (AGM, Gel, Lithium)

- Fast charging (full current even at idle)

- Protects both batteries

- Three-stage charging (bulk, absorption, float)

- Can combine with solar (most models)

- Smart (monitors battery condition)

Cons:

- More expensive (£100-220)

- Slightly more complex installation (more wires)

- Needs programming for battery type

- Can fail (electronics vs simple relay)

My experience (Van #3 & #4):

Van #3: Generic 30A DC-DC charger (£145, can’t remember brand).

Worked well for 2 years with 200Ah AGM. Charged properly.

Van #4: Victron Orion 12/12-18 (£157).

18 months of use, zero issues:

- Charges 105Ah lithium from 20% to 95% in 2.5 hours driving

- Works perfectly with smart alternator

- Bluetooth monitoring (shows voltage, current, temperature)

- Set to lithium profile (14.6V absorption)

- Never gets above warm (hand temperature)

- Absolutely bulletproof

Best feature: Bluetooth app shows exactly what’s happening (charging current, voltage, power, temperature, state). Can see charging working in real-time.

Cable sizing for DC-DC chargers:

For 18A charger (my setup):

- Input side (starter to DC-DC): 4mm² minimum, I use 6mm²

- Output side (DC-DC to leisure): 4mm² minimum, I use 6mm²

- Cable runs: 2m from starter, 1.5m to leisure

For 30A charger:

- Input: 6mm² minimum, recommend 10mm²

- Output: 6mm² minimum, recommend 10mm²

Installation complexity: Moderate. More connections than split charge relay:

- Positive from starter battery (fused)

- Negative from starter battery

- Positive to leisure battery (fused)

- Negative to leisure battery

- Ignition sense wire (optional on some models)

- Temperature sensor (optional)

Takes 2-3 hours to install properly.

Verdict: This is what everyone should use now. £157 (Victron Orion 18A) is the sweet spot. Works with any battery type. Works with modern alternators. Charges properly. Lasts forever. I’d buy the same one again tomorrow without hesitation.

Complete Wiring Guide: The Safe Way

Right. Time for the detailed bit. This is where I explain exactly how to wire it so you don’t melt cables or drain batteries.

Tools You’ll Need

Essential:

- Multimeter (£15-45)

- Wire strippers (£15-25)

- Ratchet crimpers (£25-40)

- Cable cutters (£12-18)

- Socket set (£25-60)

- Spanners (£15-30)

Useful:

- Heat gun (£20-40)

- Soldering iron (optional, £25-40)

- Label maker (£25)

- Electrical tape (£5)

Safety:

- Insulated gloves (£8)

- Safety glasses (£6)

- Fire extinguisher (£25)

Total: £171-£337 (if buying everything new)

Components You’ll Need

For a typical DC-DC charger installation (18A):

Main components:

- DC-DC charger (£100-180)

- Cable: 6mm² red (5m, £15)

- Cable: 6mm² black (5m, £15)

- Fuse holders: 2x MIDI or ANL (£8-£18)

- Fuses: 30A (2x, £5-£10)

- Battery terminals: 4x M8 ring (£8)

- Heat shrink: assorted (£6)

- Cable ties: pack of 100 (£5)

- Cable protector: 3m split loom (£8)

Optional but recommended:

- In-line switch for DC-DC (£12)

- Voltmeter near leisure battery (£8)

- Temperature sensor for DC-DC (£15)

Total materials (excluding charger): £85-£130

Grand total: £185-£310 (including 18A DC-DC charger)

Step-by-Step Installation (DC-DC Charger)

I’m going to walk through installing a Victron Orion 12/12-18 because that’s what I know intimately. Other DC-DC chargers are similar.

Location: DC-DC charger should be:

- Close to leisure battery (within 2m)

- Well-ventilated (gets warm under load)

- Accessible (you might need to adjust settings)

- Dry (not where water can drip on it)

- Away from extreme heat (not right next to heater)

I mounted mine on the wall behind the driver’s seat, 1.5m from leisure battery. Perfect location.

Step 1: Disconnect batteries (CRITICAL)

Safety first. Always.

- Turn off all systems

- Remove keys from ignition

- Disconnect NEGATIVE terminal from starter battery

- Disconnect NEGATIVE terminal from leisure battery (if already installed)

- Wait 5 minutes (capacitors discharge)

Step 2: Plan cable routes

From starter battery to DC-DC charger location:

- Through bulkhead (rubber grommet required)

- Along chassis rail

- Away from hot components (exhaust, turbo)

- Away from moving parts (steering, suspension)

- Secured every 30cm

My route: Along passenger side chassis rail, through existing bulkhead grommet (£8 grommet from Screwfix), into cargo area behind driver’s seat. Total run: 2.5m.

Step 3: Install cable from starter battery to DC-DC

Positive cable (red, 6mm²):

- At starter battery end:

- Cut cable to length plus 20cm (you’ll trim later)

- Strip 15mm insulation

- Crimp M8 ring terminal

- Heat shrink over crimp

- Route cable:

- Through bulkhead grommet

- Along chassis rail

- Secure with cable ties every 30cm

- Use split loom protector where it might chafe

- FUSE at starter battery end:

- CRITICAL: Fuse must be within 30cm of battery positive

- I use MIDI fuse holder with 30A fuse

- If fuse is further away, you risk cable fire in a short circuit

- At DC-DC end:

- Strip 10mm

- Crimp appropriate terminal for DC-DC input

- Leave slightly long (easier to trim than add)

Negative cable (black, 6mm²):

- At starter battery end:

- Crimp M8 ring terminal

- Connect to chassis near battery (clean metal, good earth point)

- NOT directly to battery negative (vehicle electronics use this)

- Route cable:

- Same route as positive (zip-tied together)

- At DC-DC end:

- Strip 10mm

- Connect to DC-DC input negative

Step 4: Install cable from DC-DC to leisure battery

Much shorter run (1-2m typically).

Positive cable (red, 6mm²):

- At DC-DC end:

- Strip 10mm

- Connect to DC-DC output positive

- Route cable:

- To leisure battery location

- Keep away from sharp edges

- FUSE at leisure battery end:

- MIDI fuse holder with 25A fuse

- Within 30cm of battery

- At leisure battery end:

- Crimp M8 ring terminal

- Ready to connect (but don’t yet)

Negative cable (black, 6mm²):

- At DC-DC end:

- Strip 10mm

- Connect to DC-DC output negative

- At leisure battery end:

- Crimp M8 ring terminal

- Ready to connect

Step 5: Mount the DC-DC charger

I used two small L-brackets (£3) and M5 bolts.

Mounted to wall panel with:

- Rubber washers (vibration dampening)

- Lock washers (won’t loosen)

- Adequate clearance around unit (10cm minimum)

Step 6: Optional connections

Ignition sense wire:

Some DC-DC chargers have this. Tells charger when engine is running.

Mine doesn’t need it (Victron Orion senses voltage rise from alternator starting). But if yours does:

- Small wire (1mm² is fine)

- Connect to ignition-live circuit (fused at 5A)

- I used the cigarette lighter circuit (check with multimeter)

Temperature sensor:

Optional but useful. Monitors battery temperature, adjusts charging.

I didn’t install one (can’t be bothered, honestly). Battery stays in comfortable temperature range.

Step 7: Double-check everything

Before connecting batteries:

- [ ] All terminals crimped properly (pull test – should not come off)

- [ ] Heat shrink over all terminals

- [ ] Fuses at both battery ends (within 30cm)

- [ ] Cables secured (no loose hanging)

- [ ] No chafing points

- [ ] Correct polarity everywhere (red = positive, black = negative)

- [ ] DC-DC charger mounted securely

- [ ] All connections tight

- [ ] Split loom over exposed cable

- [ ] Cable routes sensible (away from heat/movement)

Step 8: Connect batteries (in order)

- Connect leisure battery NEGATIVE

- Connect leisure battery POSITIVE (watch for spark – normal)

- Connect starter battery NEGATIVE

- Connect starter battery POSITIVE

Why this order? If you accidentally touch spanner to chassis while working, you won’t short circuit (negative already connected).

Step 9: Test before driving

- Check voltages with multimeter:

- Starter battery: Should be 12.5-12.8V

- Leisure battery: Should be 12.5-13.2V (depending on state)

- Turn on ignition (don’t start engine):

- Check DC-DC charger powers on (LED should light)

- Some models won’t activate until engine starts

- Start engine:

- DC-DC should activate (LED changes, or hear click)

- Check voltage at leisure battery: Should rise to 14.4-14.6V within 30 seconds

- Check current: Multimeter on output cable should show charging current

- Check for heat:

- After 5 minutes, cables should be cool to warm (not hot)

- DC-DC charger should be warm (hand temperature, not too hot to touch)

- Fuse holders should be cool

- Check connections:

- No loose wires

- No arcing or sparking

- No smell of burning

Step 10: First proper test drive

- Drive for 30 minutes

- Stop, check everything:

- Cables (should be warm, not hot)

- Terminals (tight, no looseness)

- DC-DC charger (warm, not hot)

- Voltage (leisure should be charging)

- If all good: drive another hour

- Recheck everything

- If still good: you’re done

My installation (Van #4):

Total time: 4 hours (including planning and testing)

Cables used:

- Starter to DC-DC: 2.5m of 6mm²

- DC-DC to leisure: 1.5m of 6mm²

- Total: 4m cable (bought 5m, had spare)

No issues. Works perfectly. 18 months later, still perfect.

Split Charge Relay Installation (For Comparison)

Simpler but less good. If you’re using a VSR instead of DC-DC:

Main connections:

- Positive from starter battery → Fuse (30A) → Relay input

- Positive from relay output → Fuse (25A) → Leisure battery

- Negative from relay → Chassis earth

- (Optional) Sense wire to ignition

Basically the same as DC-DC but with only one device instead of input/output sides.

Easier to install but worse performance.

Cable Sizing: The Critical Math

This is where I cocked up twice. Let me explain properly so you don’t.

Why Cable Size Matters

Cable size affects three things:

- Voltage drop (thinner = more drop = less charging)

- Heat generation (thinner = more heat = fire risk)

- Power loss (thinner = more resistance = wasted power)

The melted cable incident (Van #3):

I used 6mm² cable for a 30A DC-DC charger. Manufacturer said “6mm² rated for 50A.” Should be fine, right?

Wrong.

That 50A rating assumes:

- Short run (1m)

- Cool environment (20°C)

- Single cable (not bundled)

- Perfect ventilation

My reality:

- 3m run (longer)

- Engine bay temperatures (40-60°C)

- Cable bundled with others (shared heat)

- Against metal occasionally (conducted heat away… into metal)

Actual safe current: More like 30-35A continuous in those conditions.

At 35A continuously for 2 hours, cable got hot enough to melt insulation in one section.

Proper Cable Sizing Method

Use a cable sizing calculator or table. Don’t guess.

Factors to consider:

- Current (A)

- Cable length (m)

- Acceptable voltage drop (typically 3% max for 12V = 0.36V)

- Temperature environment

- Installation method (bundled or singles)

Simple table (12V system, 3% voltage drop, 3m run):

| Current | Cable Size (minimum) | Recommended |

|---|---|---|

| 10A | 1.5mm² | 2.5mm² |

| 20A | 2.5mm² | 4mm² |

| 30A | 4mm² | 6mm² |

| 40A | 6mm² | 10mm² |

| 60A | 10mm² | 16mm² |

| 80A | 16mm² | 25mm² |

| 100A | 16mm² | 25mm² |

For longer runs, go thicker.

Online calculators I use:

- 12VoltPlanet cable calculator (UK-specific)

- Victron cable calculator (very detailed)

Real-World Cable Choices

For 18A DC-DC charger (what I have):

Input side (starter to DC-DC):

- Minimum: 4mm²

- Recommended: 6mm² (what I use)

- Overkill: 10mm²

My run: 2.5m, I use 6mm². Cool under load.

Output side (DC-DC to leisure):

- Minimum: 4mm²

- Recommended: 6mm² (what I use)

- Overkill: 10mm²

My run: 1.5m, I use 6mm². Cool under load.

For 30A DC-DC charger:

Input side:

- Minimum: 6mm²

- Recommended: 10mm²

- Safe: 16mm²

Output side:

- Minimum: 6mm²

- Recommended: 10mm²

- Safe: 16mm²

For 40A+ systems:

Use 16mm² or 25mm². Don’t mess around. Heavy gauge is safer.

Cable cost (UK, 12V automotive cable):

- 6mm² red/black: £3-£4 per metre

- 10mm² red/black: £5-£7 per metre

- 16mm² red/black: £8-£11 per metre

- 25mm² red/black: £13-£18 per metre

My advice: Budget an extra £20-£30 and go one size thicker than minimum. Peace of mind is worth it.

Fusing: The Essential Safety Component

Fuses save your van from burning down. Take this seriously.

Why Fusing Matters

If a cable shorts to chassis (chafed insulation, crushed cable, accident damage), current can be hundreds of amps. Cable heats up instantly. Fire starts within seconds.

A properly sized fuse blows before the cable reaches dangerous temperature.

Where fuses go:

- Positive terminal of starter battery (within 30cm)

- Positive terminal of leisure battery (within 30cm)

Why within 30cm? If the short happens between battery and fuse, the fuse can’t protect that section. Keep it short.

Fuse Sizing

Fuse size should be:

- Smaller than cable rating (protects cable)

- Larger than maximum load (doesn’t blow unnecessarily)

Example: 18A DC-DC charger on 6mm² cable

- Cable rated: 50A (in perfect conditions)

- Derating for reality: 35-40A safe continuous

- Maximum load: 20A (DC-DC plus 10% margin)

- Fuse size: 30A (protects cable, handles load)

My fusing:

- Starter battery end: 30A MIDI fuse

- Leisure battery end: 25A MIDI fuse

Fuse types:

Blade fuses (automotive):

- Max size: 30A

- Not suitable for main charging circuits

- Use for small accessories only

MIDI fuses:

- 30A-100A range

- Good for charging circuits

- What I use (£8-12 for holder + fuse)

ANL fuses:

- 40A-300A range

- Better for high current

- More expensive (£12-20 for holder + fuse)

MEGA fuses:

- 80A-500A range

- Professional grade

- Expensive (£20-35 for holder + fuse)

My recommendation:

- Charging circuits: MIDI fuses (30-50A range)

- Main battery feeds: ANL fuses (80-150A range)

My Fusing Setup (Van #4)

Starter battery positive terminal:

- 30A MIDI fuse in holder (£10)

- 15cm cable to fuse

- Then run to DC-DC

Leisure battery positive terminal:

- 100A ANL fuse (main) for all systems (£18)

- Then to bus bar

- From bus bar: 25A MIDI fuse to DC-DC (£10)

Total fusing cost: £38

Common Wiring Mistakes (And How I Made Them)

Mistake 1: Undersized Cable (Van #2 & #3)

What I did: Used 6mm² for 30A continuous load

Why it’s wrong: Cable got hot. Melted insulation.

Cost: £35 new cable + £45 terminals/heat shrink + terror

Fix: Used 10mm² cable. Perfect.

Lesson: Use cable sizing calculators. Add 20% safety margin.

Mistake 2: Poor Crimping (Van #1)

What I did: Used cheap crimpers (£8 from Pound Shop)

Result: Crimps were loose. One terminal pulled off while tightening.

Cost: £15 for proper ratchet crimpers

Lesson: Buy proper ratchet crimpers (£25-40). They make perfect crimps every time.

Mistake 3: No Fuse at Leisure Battery (Van #1)

What I did: Only fused at starter battery end

Why it’s wrong: If cable shorted near leisure end, fuse couldn’t protect

Cost: Lucky – didn’t have a short. But could have been disastrous.

Fix: Added fuse at leisure battery end

Lesson: BOTH ends must be fused

Mistake 4: Fuse Too Far From Battery (Van #2)

What I did: Fuse was 80cm from starter battery (ran cable through bulkhead first, then added fuse)

Why it’s wrong: 80cm of unfused cable is fire risk

Cost: Had to redo it. Pain in the arse.

Fix: Fuse right at battery (15cm cable)

Lesson: Fuse within 30cm maximum

Mistake 5: No Cable Protection (Van #1)

What I did: Bare cable along chassis (no split loom)

Result: After 6 months, cable chafed against sharp metal edge. Nearly shorted.

Cost: £8 for split loom to protect it

Lesson: Always use split loom protection where cable could chafe

Mistake 6: Ignoring Voltage Drop (Van #2)

What I did: Long thin cables (3.5m of 6mm² for 30A load)

Result: Voltage at leisure battery: 13.8V (alternator: 14.3V)

0.5V lost to cable resistance. Slower charging.

Cost: Efficiency loss

Fix: Shorter runs (routed better), thicker cables (10mm²)

Lesson: Minimize cable length. Size cable properly.

Mistake 7: Wrong Polarity (Briefly, Van #1)

What I did: Connected positive to negative terminal by mistake (briefly, caught it immediately)

Result: Big spark. Minor panic.

Cost: Just embarrassment (and slightly singed terminal)

Lesson: Double-check polarity before final connections. Red = positive. Black = negative.

Testing Your Installation

Before you drive anywhere, test properly.

Test 1: Voltage check (engine off)

Multimeter on DC voltage (20V range):

- Starter battery: 12.5-12.8V (normal resting voltage)

- Leisure battery: 12.5-13.3V (depending on charge state)

If either is below 12.0V, charge before testing.

Test 2: Polarity check

Confirm:

- Positive terminals showing positive voltage

- No voltage between positive and earth

- No continuity between positive and negative (would indicate short)

Test 3: Engine start test

- Start engine

- Check DC-DC activates (LED or click)

- Measure voltage at leisure battery: Should rise to 14.4-14.6V within 1 minute

- Measure current (if possible): Should show charging current (10-30A depending on charger)

Test 4: Cable heat check

After 10 minutes running:

- Touch all cables: Should be cool to slightly warm

- Touch DC-DC: Should be warm (hand temperature)

- Touch fuse holders: Should be cool

- Touch terminals: Should be cool

If anything is hot (can’t touch for more than 2 seconds), STOP. Problem.

Test 5: Driving test

- Drive for 30 minutes

- Stop, recheck everything

- Drive for 2 hours

- Recheck everything

If all good after 2 hours driving, you’re sorted.

What I test every few months:

- Terminals tight (vibration can loosen them)

- Cables not chafed

- No corrosion

- Voltage still correct

Takes 10 minutes every 3 months. Worth it.

Troubleshooting Common Issues

Problem 1: Leisure Battery Not Charging

Symptoms:

- Engine running but leisure voltage stays at 12.5V

- No charging current

- DC-DC LED off

Possible causes:

A) Starter voltage too low:

- Check starter voltage with engine running

- Should be 13.8V+

- If lower, alternator problem or DC-DC won’t activate

B) Fuse blown:

- Check both fuses (starter end and leisure end)

- If blown, find out why before replacing

C) Wiring issue:

- Check continuity from starter to DC-DC

- Check continuity from DC-DC to leisure

- Check all terminals tight

D) DC-DC charger failed:

- Rare but possible

- Check power LED (should light)

- Check input voltage (should be 12-14V)

- May need replacement

E) Wrong settings:

- Check DC-DC programmed for correct battery type

- Lithium needs lithium profile

- AGM needs AGM profile

My troubleshooting process:

- Check voltages at starter battery

- Check voltages at DC-DC input

- Check voltages at DC-DC output

- Check voltages at leisure battery

This tells you where the problem is.

Problem 2: Starter Battery Being Drained

Symptoms:

- Starter battery flat after 1-2 days parked

- DC-DC or relay not isolating properly

Possible causes:

A) Relay stuck closed:

- Check relay with multimeter (should open when voltage drops)

- May be faulty (replace)

B) Reverse wiring:

- Yeah, I did this

- Check wiring diagram matches relay

- Swap if wrong

C) DC-DC not isolating:

- Most DC-DC chargers should isolate automatically

- Check settings

- May be faulty

D) Other loads on starter battery:

- Check nothing else draining starter battery

- Some van accessories stay powered

Problem 3: Cables Getting Hot

Symptoms:

- Cable warm or hot to touch after 30 minutes driving

- Smell of hot plastic

- Melting insulation

Possible causes:

A) Cable undersized (most likely):

- Check cable thickness vs current

- Replace with thicker cable immediately

- Don’t drive until fixed (fire risk)

B) Poor connection:

- Loose terminal creates resistance creates heat

- Check all terminals tight

- Re-crimp if necessary

C) Damaged cable:

- Check for crushed or damaged sections

- Replace if damaged

This is dangerous. Stop immediately if cables get hot.

Problem 4: Slow Charging

Symptoms:

- Takes 6+ hours driving to charge battery

- Charging current very low (under 10A)

Possible causes:

A) Voltage drop from thin cables:

- Measure voltage at DC-DC input vs starter battery

- If more than 0.3V difference, cables too thin

B) Weak alternator:

- Check alternator voltage (should be 13.8V+ at idle)

- If lower, alternator weak or failing

C) DC-DC limited:

- Check DC-DC rated current (18A, 30A, etc)

- May need higher rated unit

D) Battery temperature:

- Some chargers reduce current in cold weather

- Check temperature sensor if fitted

Monitoring Your System

Worth having some way to see what’s happening.

Basic monitoring (£8-15):

- Voltmeter near leisure battery

- Shows voltage (approximate state of charge)

- Cheap, simple, adequate

Better monitoring (£35-60):

- Voltmeter + ammeter

- Shows voltage and current

- Can see charging happening

Professional monitoring (£150-200):

- Battery monitor (Victron BMV-712, £185)

- Shows voltage, current, Ah consumed, state of charge, time remaining

- Bluetooth to phone app

- This is what I have – worth every penny

My monitoring setup:

Victron BMV-712 (£185) connected to leisure battery with shunt (included).

Bluetooth app on phone shows:

- Voltage: 13.2V

- Current: -15A (discharging) or +18A (charging)

- Power: -180W (discharging)

- Consumed: 35Ah out of 105Ah

- State of charge: 67%

- Time remaining: 4.7 hours at current draw

Brilliant. Know exactly what’s happening always.

When driving, can see DC-DC charging (app shows +18A). When stopped, see consumption (app shows -5A to -15A depending on what’s running).

Worth the £185? Absolutely.

Real-World Performance: My Current System

Let me show you what actually happens with proper installation.

Van #4 setup:

- Victron Orion 12/12-18 DC-DC charger

- Fogstar Drift 105Ah lithium battery

- 200W solar + Victron MPPT (separate system)

- Wiring: 6mm² throughout, properly fused, professional crimping

Typical 3-day trip:

Day 1:

- Start: Battery 85% (89Ah available)

- Drive 2 hours to location

- DC-DC charges: +36Ah (18A x 2 hours)

- Arrive: Battery 100% (105Ah)

- Evening use: Lights, fridge, laptop, water pump

- Consumption: -22Ah

- End of day: Battery 79% (83Ah)

Day 2:

- Start: Battery 79% (83Ah)

- No driving (parked up)

- Solar: +45Ah (good sunny day)

- Evening use: -20Ah

- End of day: Battery 103% (105Ah – solar topped it up)

Day 3:

- Start: Battery 100% (105Ah)

- Use all day: -25Ah

- Drive home: 1.5 hours

- DC-DC charges: +27Ah

- Arrive home: Battery 102% (full)

No issues. Never ran low. System perfect.

Winter 3-day trip (worst case):

Day 1:

- Start: Battery 90% (95Ah)

- Drive 2 hours

- DC-DC charges: +36Ah

- Arrive: Battery 100% (105Ah)

- Evening use (heating): -35Ah

- End of day: Battery 67% (70Ah)

Day 2:

- Start: Battery 67% (70Ah)

- No driving

- Solar: +12Ah (cloudy winter day)

- Evening use (heating): -33Ah

- End of day: Battery 47% (49Ah)

Day 3:

- Start: Battery 47% (49Ah)

- Use morning: -15Ah

- Battery now: 32% (34Ah)

- Drive home: 1.5 hours

- DC-DC charges: +27Ah

- Arrive home: Battery 58% (61Ah)

Got slightly low but still 32Ah remaining (never at risk). System worked perfectly even in worst case.

Cost Breakdown: Complete Systems

Budget System (Split Charge Relay) – £145-£190

Components:

- Split charge relay (30A): £35

- Cable 6mm² (6m): £20

- Fuses and holders (2x): £18

- Terminals and heat shrink: £15

- Split loom protection (3m): £8

- Cable ties and misc: £8

Tools needed (if don’t have): £150-300

Total: £254-£490 (including tools)

Performance:

- Charges at alternator voltage (13.8-14.3V)

- Slow charging (4-6 hours for 100Ah from 50%)

- Works with AGM only

- Not suitable for smart alternators

- Simple but limited

Standard System (18A DC-DC) – £280-£330

Components:

- DC-DC charger 18A (Victron): £157

- Cable 6mm² (6m): £20

- Fuses and holders (2x): £28

- Terminals and heat shrink: £20

- Split loom protection (4m): £10

- Cable ties and misc: £10

Tools needed (if don’t have): £150-300

Total: £395-£630 (including tools)

Performance:

- Proper charging voltage (14.4-14.6V)

- Fast charging (2.5-3 hours for 100Ah from 20%)

- Works with any battery type

- Works with smart alternators

- Reliable and efficient

This is what I recommend.

Premium System (30A DC-DC + Monitoring) – £515-£575

Components:

- DC-DC charger 30A (Victron): £210

- Cable 10mm² (6m): £40

- Fuses and holders (2x, larger): £35

- Battery monitor (BMV-712): £185

- Terminals and heat shrink: £25

- Split loom protection (4m): £10

- Cable ties and misc: £10

Tools needed (if don’t have): £150-300

Total: £665-£875 (including tools)

Performance:

- Fast charging (1.5-2 hours for 200Ah from 20%)

- Complete monitoring

- Professional grade

- Future-proof

For serious use or large batteries.

My Final Recommendations

After four vans, £565 in mistakes, one melted cable, and one killed alternator, here’s what I’d do:

For most people:

Buy Victron Orion 12/12-18 DC-DC charger (£157). Wire it with 6mm² cable properly fused. Done.

This is what works. Charges properly. Works with modern vans. Works with any battery type. Lasts forever.

Total cost: £280-330 (assuming you buy basic tools).

For those on tight budget:

Split charge relay is adequate IF:

- Your van is pre-2015 (non-smart alternator)

- You’re using AGM batteries

- You drive 3+ hours between stops

- Budget is really tight

Use decent relay (Durite, £35), proper cable sizes (10mm²), fuse both ends.

Total cost: £145-190.

For those with big batteries or full-time:

Victron Orion 12/12-30 (£210) + Battery monitor (£185).

Fast charging. Complete visibility.

Total cost: £515-575.

What I have and would buy again:

Victron Orion 12/12-18 (£157) 6mm² cable throughout (£20) Proper MIDI fuses both ends (£28) Victron BMV-712 monitor (£185)

Total: £390

Zero issues in 18 months. Would replicate exactly.

Final Thoughts

Split charging sounds simple. Connect alternator to leisure battery. Easy.

It’s not.

Get cable size wrong: Melted cables, potential fire. Get fusing wrong: No protection, potential fire. Wire relay backwards: Flat starter battery, stranded. Overload alternator: Dead alternator, £200-400 replacement.

I’ve made a few mistakes. Cost me a few quid and some genuinely scary moments.

But the knowledge gained means I can wire a system perfectly now. And you can too if you:

- Size cables properly (use calculators, add safety margin)

- Fuse both ends (within 30cm of batteries)

- Use DC-DC charger (not split charge relay, unless tight budget)

- Check everything twice before connecting

- Test properly before driving

- Monitor cables for heat on first few drives

The system I have now – £390 total – has been absolutely bulletproof for 18 months. Charges battery perfectly. No hot cables. No issues whatsoever.

If I built van #5 tomorrow, I’d buy exactly the same components and wire it exactly the same way. That’s how I know I finally got it right.

Now stop reading, buy a Victron Orion 12/12-18, wire it properly, and enjoy reliable charging that actually works.