I undersized my first leisure battery. Spent £120 on a 75Ah battery, thought I was being clever saving money, then ran out of power two nights into a Scotland trip. Had to drive to a campsite just to charge the bloody thing.

That’s when I learned: getting your leisure battery size right isn’t about buying the biggest one you can afford. It’s about actually calculating what you need, understanding the different battery types, and matching your setup to how you’ll actually use your van.

This guide walks through the entire process — from working out your power consumption to choosing between battery types, sizing correctly for your usage, and avoiding the expensive mistakes. Whether you’re building your first conversion or upgrading an existing system, here’s how to get it right.

So, you’re asking ‘what size leisure battery do I need?’ It’s the big question, and the answer completely depends on how you use your van. If you’re just after a simple UK weekend setup for lights and charging your phone, a 100Ah AGM battery will probably do the trick.

But if you’re living the full-time van life dream with a fridge, laptop, and a diesel heater chugging away, you’re in a different league. For that kind of setup, you’ll be looking at a minimum of 200Ah-400Ah, especially if you’re investing in lithium (LiFePO4) batteries.

Your Quick Guide to Choosing a Leisure Battery Size

Picking the right size leisure battery can feel like the single most important decision in your entire van conversion. And honestly, it pretty much is.

Get it wrong and you’ll either be crippled by constant power anxiety, checking your battery monitor every five minutes, or you’ll have spent a fortune on an oversized, overweight battery bank you didn’t need. This guide is here to steer you away from guesswork and towards a choice you can be confident in.

We’ll start with a rough estimate to get you in the right ballpark before we get into the nitty-gritty of the calculations. The aim here is to match your battery capacity to your actual lifestyle, whether you’re a weekend warrior or a full-time digital nomad.

Finding Your Starting Point

To get a feel for what you might need, it helps to think about common van usage styles. Each one has a typical power demand, giving you an instant idea of where you sit on the battery size spectrum. It’s a much better approach than plucking a number out of thin air.

The most common mistake I see is people either massively overestimating or underestimating what they need. Starting with a realistic profile of your van use—weekend trips versus full-time living—is the best way to avoid costly errors and make sure your system is actually fit for purpose.

Knowing your approximate needs is also a massive help when you’re budgeting. Lithium batteries, for instance, give you more usable power for their size but come with a hefty price tag upfront. Having a rough amp-hour number in mind helps you weigh up those trade-offs properly.

And once you’re on the road, keeping an eye on your power is just as important as the initial setup. For a deeper look into this, our guide on power management and battery monitoring systems explains how to track your energy levels properly.

The table below breaks down some common UK van life scenarios and the typical battery size they require. Find the one that sounds most like you.

Leisure Battery Size Quick Reference Guide

These are my rough estimates for required AGM battery capacity based on typical UK usage. Remember, if you’re going for Lithium (LiFePO4), you can pretty much halve these numbers.

| Usage Style | Key Appliances | Estimated Daily Ah Use | Recommended AGM Battery Size (1 Day Off-Grid) |

|---|---|---|---|

| Weekend Warrior | LED Lights, Phone Charging, Water Pump | 20-30 Ah | 85-110 Ah |

| Part-Time Adventurer | All the above + 12V Fridge, Diesel Heater | 50-70 Ah | 130-150 Ah |

| Full-Time Off-Gridder | All the above + Laptop Charging, Fan | 80-120+ Ah | 200-250+ Ah |

This should give you a solid starting point. Now you know roughly what you’re aiming for, we can move on to calculating your exact needs.

Right, let’s get down to the single most important job in your van’s electrical system: figuring out exactly how much power you actually use. Forget the online calculators and forum guesswork for a minute. The only way to move from uncertainty to a reliable setup is to do a proper power audit.

This sounds intimidating, but it’s really just an energy budget for your van. You’re going to list every single 12V appliance you plan to run, from the big power hogs like your fridge down to the tiny draws like a USB charger. Getting this right gives you the one number that everything else is built on: your total daily amp-hours (Ah). Nail this, and you won’t be left in the dark on a rainy weekend in Wales.

Creating Your Power Audit

Grab a piece of paper or fire up a spreadsheet. It’s time to list everything that will pull power from your leisure battery. For each appliance, you need two bits of info: how much power it draws (in amps or watts) and a realistic estimate of how many hours you’ll use it each day.

You can usually find the power consumption printed on the device, tucked away in its manual, or with a quick Google search. If you only find a wattage figure, a simple bit of maths gets you to amps:

Amps = Watts / Volts

Since pretty much every UK campervan system is 12V, you’ll almost always be dividing the wattage by 12. Once you know the amps for each device, you can work out its daily habit.

Daily Amp-Hours (Ah) = Amps x Hours of Use Per Day

A Practical Example of a Power Audit

Let’s walk through a common setup to see how this plays out in the real world. The key here is being honest about your usage. For instance, a 12V compressor fridge doesn’t run 24/7; it cycles on and off. A decent estimate for a fridge in the UK is that it runs for about a third of the day, so 8 hours total over a 24-hour period.

Here’s a sample calculation for a typical part-time adventurer’s van:

| Appliance | Power (Watts) | Current (Amps @ 12V) | Estimated Daily Use (Hours) | Daily Consumption (Ah) |

|---|---|---|---|---|

| 12V Fridge | 45W | 3.75A | 8 hours (cycling) | 30.0 Ah |

| Diesel Heater | 10W (avg) | 0.83A | 6 hours | 5.0 Ah |

| LED Lights | 12W (total) | 1.0A | 4 hours | 4.0 Ah |

| Water Pump | 60W | 5.0A | 0.25 hours (15 mins) | 1.25 Ah |

| USB Charger | 18W | 1.5A | 2 hours | 3.0 Ah |

| Roof Fan | 30W | 2.5A | 2 hours | 5.0 Ah |

| Total | 48.25 Ah |

In this scenario, we land on a total daily power need of roughly 48 Ah. This is the magic number, your starting point for choosing the right battery.

As you can see, the jump from occasional trips to living in your van full-time is huge. That’s precisely why a proper power audit is non-negotiable.

Refining Your Calculation

The example above is a solid base, but every van build is unique. Sizing a leisure battery in the UK really boils down to adding up the total electrical load of your specific setup. A more complex build, maybe for someone working on the road, might easily hit around 98 amp-hours (Ah) per day, which is about 1185 watt-hours.

Pro Tip: Don’t forget the sneaky “phantom loads.” I’m talking about the tiny draws from things like the display on your diesel heater controller or a USB socket with an indicator light. They seem insignificant, but over 24 hours, they can easily add up to a few amp-hours. It’s always better to slightly overestimate than to run short.

Once you have your total daily Ah figure, you’re armed with the most critical piece of the puzzle. But hold on—this isn’t the final battery size you should buy. This number just represents the usable capacity you need each day. Next, we need to account for things like battery chemistry, depth of discharge, and building in a safety net for those classic grey UK days. We’ll get into all that in the next section.

Understanding Battery Types and Usable Capacity

So, you’ve done the maths and figured out your daily power usage. The temptation now is to just buy a battery with that exact Amp-hour (Ah) number on the side. Hold on a second—it’s not quite that simple.

The number printed on a battery is its total capacity, but what you can actually get out of it is a different story. This is its usable capacity, and it’s the single most important factor that separates a happy, long-lasting electrical system from one that leaves you in the dark.

The type of battery you choose—its chemistry—dictates how much of that advertised power you can safely access without wrecking your investment. In the UK van scene, you’re really looking at three main players: traditional lead-acid, sealed AGM, and the newer Lithium Iron Phosphate (LiFePO4).

Each one has a different rulebook on how deeply you can drain it, a concept known as Depth of Discharge (DoD). Getting this wrong is the fastest way to kill your expensive batteries and undersize your system from day one.

Lead-Acid and AGM Batteries

For years, flooded lead-acid batteries and their sealed, maintenance-free cousins, Absorbent Glass Mat (AGM), were the go-to option. They’re cheap and you can find them anywhere, but they come with a hefty trade-off.

To avoid permanently damaging them and drastically shortening their lifespan, you should only ever discharge them to about 50% of their total capacity. Think of it as a non-negotiable rule.

- A 100Ah Lead-Acid/AGM battery gives you just 50Ah of usable energy.

- A 200Ah Lead-Acid/AGM battery gives you only 100Ah of usable energy.

This completely changes the game. If your daily power audit came out at 48Ah, you’d need a 100Ah AGM battery just to get through a single day without causing harm. On top of that, they are seriously heavy, which is a real problem when you’re trying to stay under your van’s payload limit.

Be careful not to confuse leisure batteries with standard starter batteries. A starter battery is built for one job: delivering a massive, short burst of power to turn an engine over. It can only handle maybe 20-30 deep discharge cycles before it dies. Leisure batteries, on the other hand, are designed to provide a steady, lower current over a long period and can endure hundreds of cycles. They are essential for any off-grid setup.

Lithium Iron Phosphate (LiFePO4) Batteries

Lithium is the new gold standard in the van life world, and for very good reasons. Yes, the upfront cost is a lot higher, but the performance leap is massive.

The killer feature is their usable capacity. You can safely and regularly discharge a LiFePO4 battery to 80-95% of its total capacity without breaking a sweat.

This flips the sizing equation on its head:

- A 100Ah Lithium battery gives you 80-95Ah of usable energy.

All of a sudden, a single 100Ah lithium battery can deliver almost double the power of its AGM equivalent. This means you can get away with a smaller and, crucially, much lighter battery bank. A typical 100Ah AGM battery weighs around 25-30kg; a 100Ah lithium battery is often just 11-13kg. That’s a huge weight saving.

Why Chemistry Matters for Sizing

Let’s go back to our 48Ah daily usage example. To meet that need, you’d have to choose between:

- AGM Solution: A minimum 100Ah battery (because 50% of 100Ah is 50Ah).

- Lithium Solution: A 60Ah battery would be enough (because 80% of 60Ah is 48Ah).

The lithium option provides the same power in a package that’s smaller, lighter, and will last for thousands of charge cycles instead of just a few hundred. This is exactly why so many UK van builders are now making the jump to lithium—it simplifies the entire system and buys you long-term peace of mind.

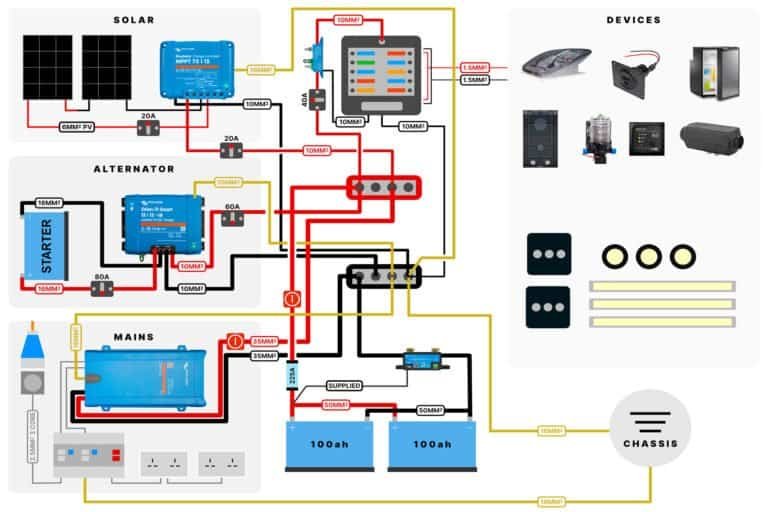

For a more detailed look at how these components fit together, check out our full guide on campervan electrical systems explained.

Adjusting for Real-World UK Conditions

Your on-paper calculation is a brilliant starting point, but it assumes a perfect world. UK van life is rarely perfect. It’s full of grey days, cold snaps, and the sudden urge to charge a power tool in the middle of nowhere. This is where we stop theorising and start building a resilient, real-world system.

Just taking your daily amp-hour figure and buying a battery to match is a classic rookie mistake, and it’s a surefire recipe for power anxiety. To build a system that you can actually rely on, you need to account for the beautifully unpredictable nature of life on the road, especially in Britain.

The All-Important Safety Margin

First things first, let’s add a safety buffer. Think of it as your contingency plan for when the weather forecast is a complete lie, which it often is. For UK conditions, I always tell people to add a 20-25% safety margin to their total daily power usage.

Why? Because you will get a week of relentless cloud and rain where your solar panels generate next to nothing. This buffer is what stops a few overcast days from turning into a desperate search for a campsite with an electric hook-up. Trust me, building in this extra capacity is the single best way to keep the lights on when you need them most.

Let’s go back to our earlier example of a 48Ah daily need. Adding a 25% safety margin looks like this:

48 Ah x 1.25 = 60 Ah

Your new target for daily usable capacity is 60Ah. That small increase on paper makes a huge difference in real-world confidence.

The Inverter Inefficiency Tax

If you plan on running any 230V mains appliances—like your laptop charger, a blender, or camera batteries—you’ll need an inverter. An inverter’s job is to convert the 12V DC power from your batteries into 230V AC power, but this conversion isn’t free. Energy is always lost in the process.

Inverters use power just to be switched on, and they lose more energy as heat while they’re working. This inefficiency typically eats up around 10-15% of the power they draw. You have to account for this “tax” in your sums, otherwise you’ll be using more power than you budgeted for.

A good rule of thumb is to increase the power requirement for any AC appliance by 15%.

- Example: A 65W laptop charger doesn’t just pull 65W from your battery.

- Run through an inverter, it’s actually drawing closer to 75W (65W x 1.15).

- That little bump turns a 5.4A load into a 6.25A load, which adds up surprisingly quickly over a few hours of work.

The Impact of UK Winters

Temperature has a massive, and often overlooked, effect on battery performance. The cold, damp UK winters can seriously reduce the effective capacity of your battery bank, especially if you’re using older lead-acid or AGM types.

As the temperature drops towards freezing, a lead-acid battery’s chemical reaction slows right down, making it much harder for it to release its stored energy. An AGM battery can lose up to 20% of its capacity at 0°C and a whopping 50% at -20°C. If your battery lives inside your insulated van, this is less of an issue, but it’s a critical factor for batteries stored in unheated external boxes.

Lithium (LiFePO4) batteries are much, much better in the cold but they still have limits. Most can’t be charged below 0°C without risking permanent damage, though many newer models now come with clever built-in heaters to get around this.

When you’re figuring out what size leisure battery you need for year-round travel, this winter performance drop is a compelling reason to oversize your bank or, if the budget stretches, to invest in lithium. Having reliable power on a dark, frosty morning is absolutely non-negotiable. And since solar is your main charging source, our guide on choosing the right solar panels for your van will help you squeeze every last watt out of those short winter days.

Putting It All Together with Sizing Examples

Theory is great, but let’s put some real-world numbers on it. I’m going to walk you through three classic UK van life scenarios, applying everything we’ve just covered—the power audit, battery chemistry, and those crucial real-world adjustments.

You’ll see just how quickly the answer to “what size leisure battery do I need?” changes when you add a single power-hungry appliance or swap from an old-school AGM to modern lithium. For each profile, we’ll crunch the numbers for both an AGM and a Lithium (LiFePO4) system to show you the practical difference.

The Weekend Warrior

This is your classic setup for short trips and festival weekends. The power needs are pretty minimal; we’re talking comfort and convenience, not full-time living.

- Appliances: Just the basics—some LED lights, phone charging, and a water pump.

- Daily Power Need: A quick power audit puts their daily consumption at around 25Ah.

- Safety Margin: We’ll add a 25% buffer for an extra device or a cloudy day, which brings our target to 31.25Ah of usable power.

For an AGM battery, which you should only ever discharge to 50%, we need to double that number.

31.25Ah (Usable) x 2 = 62.5Ah (Total Capacity)

The nearest standard size you’ll find is an 85Ah AGM battery. This gives a comfortable buffer without adding pointless weight or cost for occasional trips.

Now, let’s look at a Lithium (LiFePO4) battery. With its deep 90% usable capacity, the maths is a whole different ball game.

31.25Ah (Usable) / 0.9 = 34.7Ah (Total Capacity)

A tiny 40Ah Lithium battery would handle this with ease. It would be dramatically lighter and take up much less space than the 85Ah AGM, making it a fantastic (though more expensive) choice for a compact van.

The Part-Time Adventurer

This person is spending longer stints off-grid, maybe a week at a time exploring the Scottish Highlands. Their setup is a step up, with some serious power consumers like a fridge and a heater.

- Appliances: Everything the weekend warrior has, plus a 12V compressor fridge and a diesel heater.

- Daily Power Need: That fridge and heater bump the daily total right up to 60Ah.

- Safety Margin: A 25% buffer brings the daily usable target to 75Ah.

For an AGM system, this bigger demand calls for a much larger battery bank.

75Ah (Usable) x 2 = 150Ah (Total Capacity)

A single 150Ah AGM battery is the absolute minimum here. It’s a hefty unit, often weighing over 40kg, but it’s a reliable workhorse for this level of use.

And for the Lithium (LiFePO4) alternative?

75Ah (Usable) / 0.9 = 83.3Ah (Total Capacity)

A single 100Ah Lithium battery is the perfect fit. It delivers more usable power than required, weighs less than half of the AGM equivalent, and will last many times longer. It’s an excellent long-term investment.

Worked Example Comparison AGM vs Lithium (LiFePO4)

Let’s pause and compare the two solutions for our ‘Part-Time Adventurer’. It’s a perfect illustration of how the upfront cost of lithium pays dividends in weight, space, and longevity.

| Factor | AGM Battery Solution | Lithium (LiFePO4) Solution |

|---|---|---|

| Required Capacity | 150Ah | 100Ah |

| Usable Capacity | ~75Ah | ~90Ah |

| Typical Weight | ~40-45 kg | ~11-13 kg |

| Lifespan | 300-700 cycles | 3000-5000+ cycles |

| Upfront Cost | Lower | Higher |

As you can see, while the AGM is cheaper to buy today, the lithium option provides more usable power in a package that’s nearly four times lighter and will last almost ten times as long. This is the trade-off you’re constantly making in a van build.

The Full-Time Off-Gridder

This is the digital nomad or full-time van lifer. Their electrical system is their lifeline, powering work and daily living. They’ll be running 230V appliances through an inverter, which adds another layer to our calculations.

- Appliances: All of the above, plus regular laptop charging via an inverter.

- Daily Power Need: The previous 60Ah plus an estimated 25Ah for the laptop (which includes the 15% inverter inefficiency), bringing the total to 85Ah.

- Safety Margin: A 25% buffer means we’re aiming for a daily usable target of 106.25Ah.

For a robust AGM system, you’re now looking at a seriously chunky battery bank.

106.25Ah (Usable) x 2 = 212.5Ah (Total Capacity)

To hit that number, you’d need at least a 220Ah AGM battery, or more likely, two 110Ah batteries wired in parallel. This is a very heavy, space-hungry solution.

This scenario is where a Lithium (LiFePO4) system really comes into its own.

106.25Ah (Usable) / 0.9 = 118Ah (Total Capacity)

A 120Ah or 130Ah Lithium battery would handle this without breaking a sweat. In my experience, most full-timers would opt for a 200Ah lithium setup to give them almost two full days of power in reserve without needing a charge—a crucial buffer for those grey UK winters.

To help UK buyers navigate this, the National Caravan Council (NCC) categorises leisure batteries. Category A batteries are for high-demand, off-grid use, which is exactly what our Full-Timer needs. Category B suits the Part-Time Adventurer who might occasionally use hook-ups, while Category C is ideal for the Weekend Warrior’s basic requirements.

Ultimately, these examples show there’s no single “right” answer. The best battery size is always the one that’s properly matched to your specific appliances and travel style.

Final Checks: Common Questions Before You Buy

Even with all the calculations done, a few last-minute questions always seem to pop up just as you’re about to click “buy”. I’ve been there. Getting these final details straight is the last step to building a system you can actually trust when you’re parked up in the middle of nowhere. Let’s tackle the most common ones.

Can I Mix Different Leisure Batteries?

This comes up all the time, and the answer is a hard no. You should never, ever mix leisure batteries of different types (like AGM with Lithium), different ages, or even different capacities in the same bank.

When you connect batteries, they constantly try to equalise with each other. A tired, older battery will relentlessly drain a brand-new one, crippling its performance and dramatically shortening the lifespan of both. It’s a false economy that guarantees you’ll be buying a whole new set of batteries much sooner than you planned. Always start fresh with identical, matched batteries.

The golden rule for battery banks is simple: keep it uniform. Mismatched batteries are like a dysfunctional team where one member is always doing too much work and the other isn’t pulling its weight. It’s the fastest way I know to ruin a brand-new, expensive battery and undermine your entire electrical system.

How Much Solar Do I Need for My Battery?

A solid rule of thumb for the notoriously unreliable UK weather is to aim for a solar array (in watts) that’s roughly 1.5 to 2 times your battery bank’s capacity (in amp-hours).

- For a 100Ah battery, you’ll want between 150W and 200W of solar.

- For a 200Ah battery bank, you should be looking at 300W to 400W of solar.

This ratio gives you a fighting chance of fully recharging your batteries, even on the grey, overcast days we’re all too familiar with in Britain. It should be enough to replace what you use each day, keeping your system topped up and healthy without constantly needing to start the engine or hunt for a campsite hook-up.

Is a Battery Monitor Really Necessary?

Yes. 100% yes. A proper battery monitor isn’t a luxury; it’s one of the most critical investments you can make in your van’s electrical setup. Trying to manage your power without one is like driving at night with no headlights.

Just relying on voltage is a notoriously bad way to guess your battery’s charge level, especially with lithium batteries, which maintain a stubbornly stable voltage right until they’re about to die. A proper shunt-based monitor, like the ones from Victron, doesn’t guess – it measures the actual energy flowing in and out of your battery.

This gives you a precise state-of-charge percentage, just like the battery icon on your phone. Knowing you have exactly 42% left is crucial for managing your power properly and, most importantly, protecting your batteries from being discharged too deeply. That’s the number one killer of expensive leisure batteries. A monitor removes the guesswork and buys you peace of mind.

At The Feral Way, we believe in building smart, reliable systems that last. For more real-world advice and tested build guides, explore everything we have to offer at https://theferalway.com.